It’s been a busy summer here at Fish Mart as we did routine maintenance and got some projects done. The biggest project was upgrading the filtration units on two of our largest aquatic life support systems.

The redesign called for 4 energy-efficient pumps to replace what used to be two non-energy efficient pumps. These new pumps also have controls so that we can adjust the speed of the water flow, and have LED displays. Two pumps circulate the water, and the other two pumps are for the filtration modules. Each module is comprised of the following –

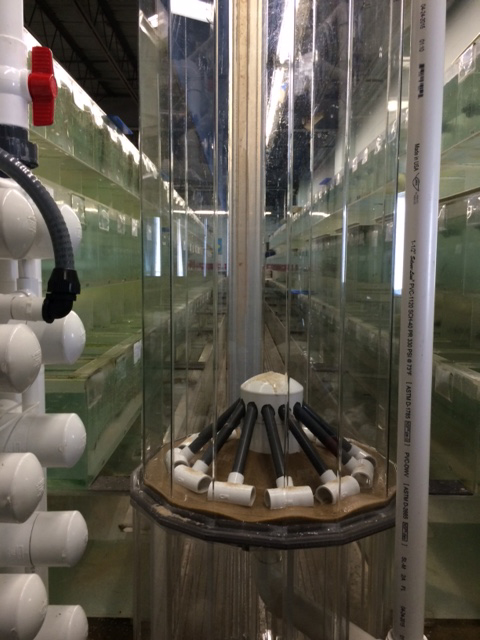

- 2 huge acrylic columns that are fluidized filter beds for biological filtration (each with about 1 million square miles of surface area for the good nitrifying bacteria to live on, ensuring water free of any ammonia or nitrites, and only a minimum of acceptable nitrates);

- a 12-tube ultraviolet unit (the UV kills free-swimming microorganisms such as bacteria, parasites, algae and even some viruses in the water that passes over it);

- a protein skimmer (which is a device used to remove organic compounds such as food and waste particles from water, while also adding oxygen);

- a de-gasser (which removes potentially unwanted gasses while also adding oxygen;

- ozone (to oxidize organic materials);

- and of course mechanical filtration to remove suspended particulates.

All this is to guarantee the best water quality possible, making for the healthiest and most stress-free fish possible!

Our imported goldfish system got a filtration upgrade as well, as we doubled the UV capacity to ensure maximum reduction of any free-swimming microorganisms.

LED lighting throughout the entire warehouse facility and even offices is underway. Not only is this project energy-efficient and therefore cost-effective, the lighting enhancement is nothing short of phenomenal. We are doing this in stages, but the main fish warehouse rooms are about complete.

Staying in the fish warehouse, new packing tables have also been designed and are under production.

In the animal department, refreshing the many Freedom Breeder units, which house most all the pets -from mice and rats to gerbils, guinea pigs, hamsters and more – is continually being done. Time-consuming, each unit has to be stripped of any rust, sanded and repainted.

Routine repairs and maintenance in a number of areas has also been ongoing. Some patching and re-painting on the cement block building exterior was necessary. Some touch-up painting inside has also occurred. Even the entrance doors to Fish Mart needed replacement, this after over 20 years of much use.

It’s been a busy year, as we continuously strive to always provide our customers with the highest quality aquatics and pets, in an environment that is necessary to do so.